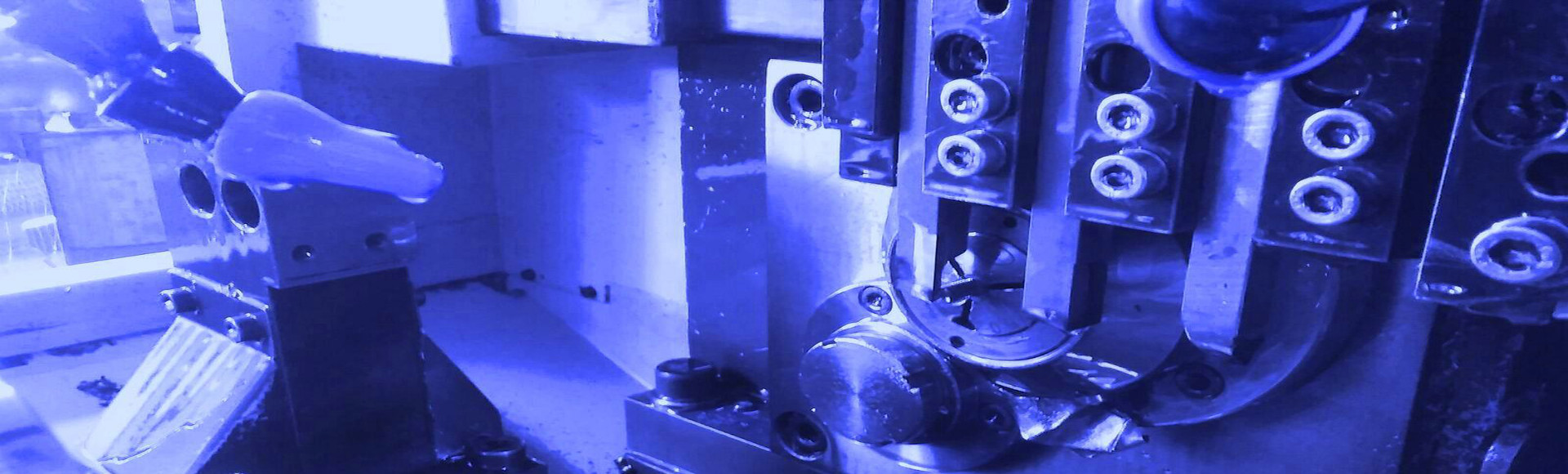

We manufacture precision turned parts from 0.5 to 20mm diameter on Swiss-type automatic lathes and lathes with fixed headstock. We can use coil and bar material. Our machinery is partly CNC and partly conventionally driven. The larger part of our capacity is below 7mm diameter.

All our machines are suited for rear-end machining; most machines are also suited for cross-holes and milling. The use of contour tools and profile material gives us options to reach complex contours in a quick and simple manner. Thus, we can offer competitive pricing for precision turned parts with complex outer contours, several bores, inner and outer threads, cross-holes and simple milling contours.

The right combination of raw material and further processing steps allows us to produce axles with high surface qualities in a very economic way. Furthermore, we have a wide range of experience with knurling and the production of brass contact pins.

The production of articles with very high quantities is carried out on rotary transfer machines with several simultaneous machining stations.